One of the most important parts of the Witchcliffe Ecovillage development is its sewerage treatment plant, or water recovery facility project, as it is described by its licensed operator, Tony Johansen of TMC Witchcliffe. Without this, WEV simply would not be able to achieve housing density in the Ecovillage, which in turn would mean none of the design principles and community scale we were seeking would be possible. I bet you never thought about sewerage in those terms before!

Article below by Tony Johansen, owner and operator of TMC Witchcliffe

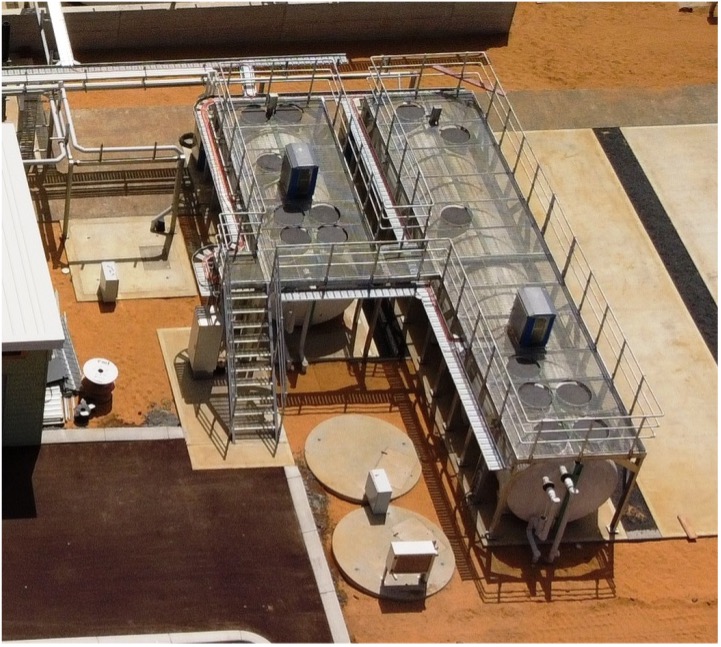

Earthworks to construct the site pad for this new community-scale facility, AKA The Green Iguana, commenced in December 2020. Now in April 2023, we are approaching the exciting and challenging period of commissioning the complex array of equipment, which will ultimately to be controlled by System Control and Data Acquisition software (SCADA).

The base technology is MBBR (Moving Bed Bio Reactor), which is enclosed in sealed tanks to in part manage odour. MBBR’s have many advantages over traditional systems too numerous to describe in this article, but the main driver for the process selection was the reduced footprint and high efficiency in processing organic contaminants such as carbon, nitrogen and phosphorous, which is typical of wastewater.

The MBBR process was invented by Prof Halvard Odegaad at the Norwegian University of Science and Technology in the late 1980’s. Today MBBR’s are installed in decentralized facilities around the world in projects similar size to the Ecovillage. China arguably leads the way in decentralization of water facilities. The project selected a leading Chinese supplier of MBBR’s that has a wide experience of success in local and international installations.

The project is designed on a modular platform where additional MBBR reactors can be installed as the Ecovillage expands to its physical completion. Building a facility to suit the Ecovillage’s final capacity on day one would be plagued with operational issues in the early years of operation.

The facility comprises an operational office, laboratory, screening room, pump room, dewatering room, tank farm, odour control and irrigation lagoon. We have deliberately hidden most of the equipment to ensure aesthetic appeal and to protect expensive equipment from the elements. One of our aims was to build a facility that does not look like a typical wastewater plant and one that blends into the environment.

Of major concern to us and the developer was odour, which is typically characteristic of wastewater plants. We installed a system from local Perth company Odatech that draws gasses developed in the plant through compost beds located in the two green poly tanks then finally scrubbed with activated carbon. We anticipate zero odour from normal operation. After approximately five years, the compost is exchanged and the old compost is then suitable for gardens.

Currently, TMC Witchcliffe is concentrating on the commissioning of the screening room equipment and finalising the SCADA controls to a point where we can accept the output from the Ecovillage pump stations.

The SCADA is the “brain” that makes decisions on information we supply enabling the site to be unmanned. In reality, the site will be manned during the day with the SCADA working in the background collecting information to enable us to fine tune the process based on real time data acquisition. No guessing, but continuous refinement.

Future work on site will include the installation of three more 40kL/d MBBR modules, the completed plant will have a total capacity of 160kL/d. Our present capacity is 65kL/d with the Ecovillage generating approximately 7kL/d that is processed offsite.

Our aim is to reduce the visual impact on the environment through site landscaping and beautification, which will comprise a specialised selection of various plants, ground covers and shrubs.

Similar to the rest of the Ecovillage, power is critical to sustainability. We have initially installed 40kW of solar panels, expanding to 80kW. At completion the site will aim to generate 160kW of solar power thereby substantially reducing our dependence on grid power. The plant operates 24/7 while everyone is sleeping, so storing energy during the day to offset night-time power demand is part of the overall site plan, one of several strategies that will be incorporated.

Another action we’re taking is to process dead bacteria (sludge) into compost by mixing it with other local materials such as wine marc and woodchips. The SCADA will enable us to make decisions on when and how large the composting facility will need to be. In line with the design philosophy of the site, the composting will be totally “in vessel” and housed in a dedicated building.

We’re thrilled to be involved with such a groundbreaking project, and now that we’re about to start operations, we’re excited about working with such an educated community, who we know will work with us to improve the operation of the plant by following our advice on what products to avoid flushing down toilets and sinks. Our major “blue sky” project is the post treatment of biologically treated water to remove pharmaceuticals, at a level not done anywhere in Australia.

The future is full of challenges and ground-breaking research where we will seek support from academia and NGO’s.